FMG SensorBlade

Cost-effective road maintenance system – always along

INNOVATION!

Now Valtra T4 and T5-series tractors get high quality and more technically advanced FMG Sensor Blade underbody scraper.

WHY UNDERBODY SCRAPER?

Underbody scraper is cost-effective road maintenance system that is always along.

The underbody scraper doesn’t hinder to use other work equipment and gives possibility to use the front lift, hitch and/or front loader. Also, all hydraulic blocks of the tractor are free for usage with other work equipment.

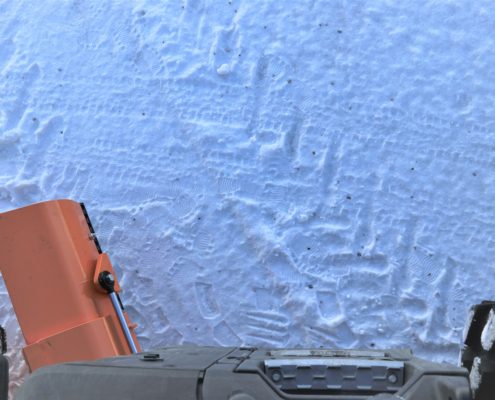

The underbody scraper located in the middle of the tractor is stable to use. A lot of force with the mass of the tractor can be applied to the underbody scraper.

The underbody scraper has a large working width, but the transport width is small. It is almost unnoticeable during transportation. The underbody scraper doesn’t affect visibility compared to other equipment.

WHY EXACTLY FMG SENSOR BLADE UNDERBODY SCRAPER?

Sensor Tech control system

FMG Sensor blade is equipped with Sensor Tech control system. All functions of underbody scraper are controlled by one joystick, which makes using of the underbody scraper ergonomic, logical and versatile. The activities of underbody scraper are displayed on the 5.7″ touch screen. Numerical traceability and graphic symbols make adjustment and usage of the underbody scraper easy.

High clearance

| Clearance in the transport position | (T4 stg4, Nokian Ground King 42″) | 260mm | |

The underbody scraper has 260 mm ground clearance in the transport position, which enables the normal tractor use.

When the scraper is up in work position, the clearance is 150 mm. Then the scraper is ready for work: blade goes down quickly to the work position and enables to adjust the needed turning angle before blade touches ground.

FMG 3D blade control.

The height, tilt and rotation adjustments of the blade give versatile possibilities for shaping the road.

Multislider extension wings

The unique structure of the extension wing.

Remote connection

Through mobile APP is possible to update the software, make the diagnostics and control the hydraulics (adjustment of movement speed).

Ergonomic working position

Screen and joystick enable the driver to have an ergonomic working position.

Centralized lubrication system

Centralized lubrication system is included to the standard equipment. It makes lubrication easy and save time during maintenance.

Stinger blade

Stinger blades are included to the standard equipment. Stinger blades suits well for gravel road maintenance at summer and ice removal at winter.

Unique construction

FMG Sensor blade don’t have external vertical cylinders, which reduces the risk of breakage. The geometry of the blade enables smooth movement of the material. The turning angle is symmetrical on both sides. Accurate hydraulically adjustable turning angle (+/- 25 degrees).

EQUIPMENT

Standard equipment: centralized lubrication system, stinger blade, FMG 3D blade control, multislider extension wings, Sensor Tech control system, remote connection, joystick and screen with RAM B adapter, blade can be easily removed if necessary.

Optional equipment: wiring harness for the Sensor Tech control of TLN road draggers, grader assembly in Iisalmi.

Technical specifications

Vieritä taulukkoa nähdäksesi sen kokonaan

| Model | AT-SB |

|---|---|

| Transportation width | 2480 mm |

| Working width | 2256 mm – 3376 mm |

| Working width with max. turning angle | 2256 mm -3093 mm |

| Turning angle | +/- 25 degree |

| Side tilting | +/-5 degree |

| Weight | 1055 kg |

| Height of the blade | 416 mm |

| Extension dimensions / side (additional working width) | 450 mm |

| Extension dimensions / side (additional working width with turning angle) | 419 mm |

| Ground clearance in work position(T4 stg4, Nokian Ground King 42″) | 150 mm |

| Ground clearance in the transport position (T4 stg4, Nokian Ground King 42″) | 260 mm |